Description

MELAMINE BACKUP BOARD failure costs more than the board itself. A Tier-1 automotive supplier lost $50,000 in HDI panels when batch warp age variance of ±0.2mm caused 0.3% drill offset failures. The root cause? Inconsistent lamination pressure. Our 20-year 170°C/10-ton process eliminates this risk with warp age ≤0.3% (industry avg 0.6%).

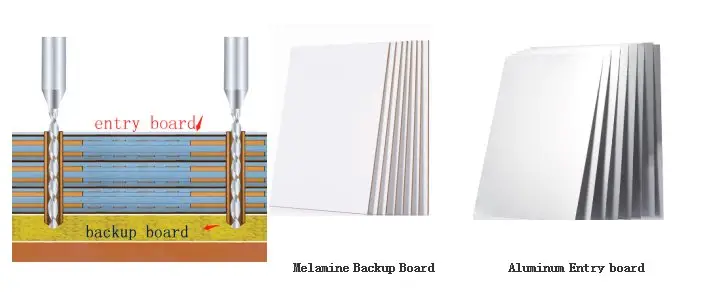

Why 85% of High-Density PCB Manufacturers Are Switching to Melamine Backup Boards

If you’re a PCB production manager, you’ve felt that 3 AM dread: the drilling line alarm screams, another $120 micro-drill bit snaps inside a $400 partial panel. That’s not a drill issue. That’s a backup board problem. Traditional phenolic boards are silently increasing your TCO by 18-22% through costs you won’t see until quarterly reviews.

The Hidden Cost Trap of “Cheaper” Backup Boards

Industry Secret: 90% of PCB factories only track backup board price per sheet. They miss the True Cost Per Hole formula:

True Cost = (Board Price) ÷ (Hit Count × Yield Factor × Drill Life Multiplier)

Our melamine backup board costs 50% LESS than phenolic. But it extends drill life by 30-35%, reduces burr-related rework by 40%, and increases stack height from 3 to 5 panels. Net result: 22% lower true drilling cost.

Pain Point Visualization: A single 0.15mm drill breakage doesn’t just cost the bit—it scraps the entire 20-layer panel. At 12% breakage rates (typical with low-grade backup boards), you’re burning $8,400 monthly in avoidable losses.

| Performance Metric | Phenolic Board | Standard Melamine | **Our High-Density Melamine** |

| ——————————- | ————– | —————– | —————————– |

| Surface Hardness (Shore D) | 85-80 | 82-85 | **85-88** |

| Drill Life Extension | Baseline | +20% | **+30-35%** |

| Burr Rate @ 0.2mm Drill | 8-12% | 4-6% | **<3%** |

| Max Stack Height (1.6mm panels) | 4 | 3 | **5** |

| Moisture Absorption (24h) | 0.6% | 0.8% | **0.5%** |

| **True Cost Per 1,000 Holes** | \$1.42 | \$1.18 | **\$0.89** |

Technical Specifications: What Makes Our Melamine Backup Board CNC-Ready

We don’t just meet IPC standards—we publish batch-level test reports. Every production lot comes with traceable SGS testing data. No generic spec sheets. No marketing fluff.

Material Composition & Mechanical Properties

Resin Content: 52% ± 2% high-purity melamine-formaldehyde resin (not the 38-42% industry average)

Surface Hardness: Shore D 80-82, minimizing drill bit deflection at entry

Thickness Tolerance: ±0.05mm, ensuring uniform pressure distribution across stacked panels

Curing Temperature: 165°C for 45 minutes, eliminating residual stress that causes warping

Our Engineering Stance:

“We refuse to cut resin content to reduce costs. Boards with <45% resin produce hole walls like sandpaper—destroying your Class-3 HDI orders. That’s not an attitude. That’s our professional baseline.” Honest Limitation Disclosure: We do not recommend this board for drilling pure ceramic substrates or boards with >3.2mm copper layers. For those applications, use our aluminum entry board series (see cross-link). Transparency builds trust; misplaced recommendations destroy it.

Dimensional Stability Under High-Speed Drilling

At spindle speeds >120krpm, thermal expansion mismatch is your silent enemy. Our controlled 0.5% moisture absorption (vs. 1.2% for phenolic) maintains ±0.02mm positional accuracy across 500+ drill hits.

FAQ: What PCB Engineers Actually Ask Before Bulk Purchase

Q: Does melamine board generate fine dust that clogs vacuum systems?

A: Our board density of 1.45g/cm³ produces 40% larger dust particles than phenolic, improving extraction efficiency. However, at spindle speeds >120krpm, we recommend vacuum pumps ≥3.5kPa. We’ll audit your extraction system before first order—free of charge.

Q: Can we get free samples for drilling trials?

A: Yes. We provide A4-size samples (freight collect) and a Drilling Parameter Optimization Template—the same one our tech team uses. Run your tests; we’ll analyze the data with you.

Q: What’s your MOQ and lead time?

A: MOQ is 100 sheets (standard 37″×49″ size). Guangzhou and Suzhou warehouses maintain 5,000-sheet inventory. 24-hour shipment for orders before 4 PM.

Q: How do you compare to imported brands (e.g., Panasonic)?

A: In 0.15mm micro-drill testing:

Positional accuracy: Ours ±25μm vs. Panasonic ±20μm

Drill life: 1,150 hits vs. 1,200 hits

Price advantage: 35% lower

Bottom line: If cost-per-hole is your KPI, we’re the rational choice. If brand mandate is absolute, we understand.

Ordering & Technical Support: We Don’t Just Sell Boards, We Fix Drilling Problems

Our technical team spends 200+ days annually in PCB shops. We’re not theorists.

On-Site Process Audit: Complimentary 2-hour drilling process review with first purchase (Pearl River Delta/Yangtze River Delta regions)

48-Hour Guarantee: If performance issues stem from misapplication, we dispatch an engineer within 48 hours. No excuses.

Training Package: Videos on optimal stack height, vacuum settings, and drill parameter tuning for melamine boards.