Superior alternative of melamine backup board for PCB Drilling

“not easy to be warp or deform,Excellently applied for FPCB and other high-end PCB drilling with micro-holes,φ0.15mm for example, as backing board, and more environment friendly for waste disposal”

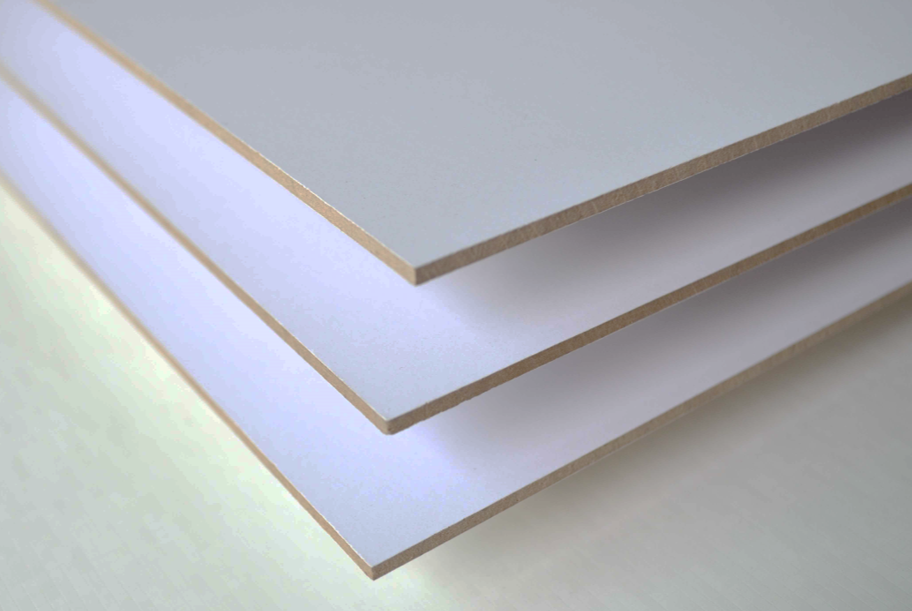

In the ever-evolving landscape of PCB (Printed Circuit Board) manufacturing, the choice of materials plays a crucial role in ensuring efficiency and quality. Among these materials, UV coated white backup boards have emerged as a leading alternative to traditional phenolic boards and water-based paint boards. This blog explores the unique features, advantages, and applications of UV coated white backing boards, highlighting why they are becoming the preferred choice for high-end PCB drilling, especially in the context of their protective qualities.

Backing board Material Product Description

UV coated white backup boards are crafted from high-density wood fiber board, which is then coated with a specialized UV paint, offering enhanced protection against environmental factors. This coating process involves a rapid curing method under ultraviolet light, which not only enhances the smoothness of the surface but also significantly increases its hardness compared to water-based alternatives.

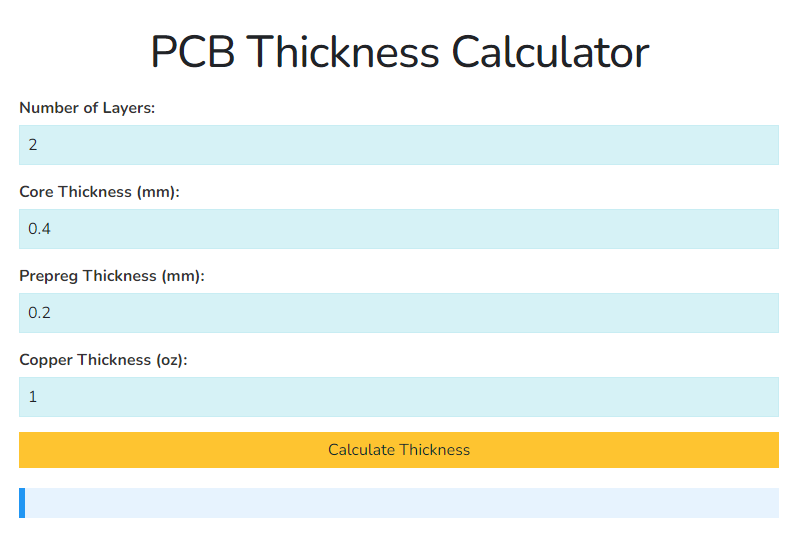

- Thickness: Typically available in thicknesses of 2.5 mm ± 0.1 mm, ensuring precise dimensions for high-density interconnect designs. and 2.7 mm, a measurement critical for achieving desired performance in specialized designs., providing flexibility for various applications.

- Density is a key factor in determining the performance and suitability of materials for board for PCB drilling applications.: The boards boast a density of ≥880 kg/m³, with options up to 950 kg/m³ to achieve enhanced hardness.

- Hardness is an important characteristic of the drill backup used in PCB applications.: The surface hardness reaches approximately 78 ± 5 Shore D, ensuring durability and resistance to wear.

- Warpage Tolerance is a critical factor when selecting materials for board for PCB drilling.: With a warpage tolerance of ≤0.5%, these boards maintain their structural integrity even under demanding conditions.

Compare Advantages Over backing Materials

- Enhanced Surface Quality:

- UV coatings provide a smoother finish compared to water-based paints, which can suffer from imperfections due to evaporation and shrinkage during natural drying. This smoothness is critical in minimizing burrs and reducing hole wall roughness during drilling.

- Superior Hardness and Durability:

- The hardness of UV coatings is typically 2-3 degrees higher than that of water-based paints, resulting in better wear resistance and scratch resistance. This characteristic is essential for maintaining drill bit integrity and prolonging their lifespan.

- Environmental Considerations:

- Both UV coatings and water-based paints are free from volatile organic compounds (VOCs), making them environmentally friendly options. However, UV coatings offer superior performance without compromising on ecological standards, showcasing the latest technology in sustainable manufacturing.

- Dimensional Stability:

- The unique curing process of UV coatings reduces the likelihood of warping compared to traditional high-temperature and high-pressure methods used in producing phenolic boards, making them a special choice for manufacturers. This stability is achieved through careful formulation and consistent application techniques, ensuring optimal protection for the final product.

uv coat Applications in PCB Drilling

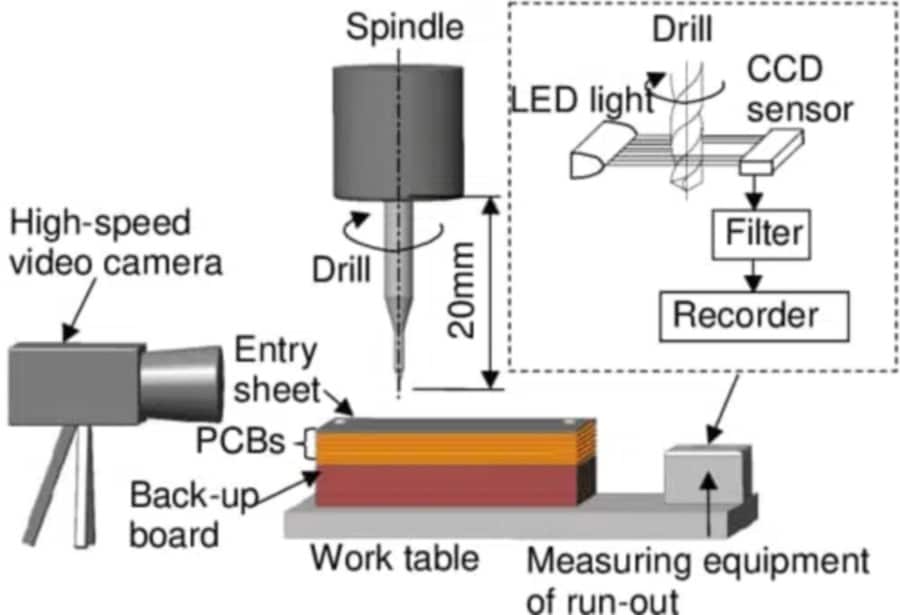

UV coated white backup boards are particularly suited for high-precision applications, designed to meet strict quality standards.

- They provide a flat, high-density surface that minimizes drill breakage and enhances hole position accuracy.

- Ideal for drilling micro-holes down to 0.15 mm, making them perfect for high-density interconnect (HDI) PCBs and flexible circuit boards (FPCBs), which require advanced design considerations.

- Their properties ensure that they can effectively support multi-layer circuit boards, especially those requiring pinhole apertures.

Quality checking Measures on PCB Backup Boards

Use high-quality substrates with good thermal stability and uniform thickness to prevent warping and stress concentrations.

Implement symmetrical designs and balanced copper distribution to ensure even stress distribution and minimize warping.

Maintain consistent temperatures and manage humidity in production to prevent thermal stress and moisture absorption

Conduct thorough visual inspections and dimensional checks to identify defects and ensure compliance with specifications

Store boards flat and avoid stacking; train staff on proper handling techniques to reduce physical stress

Implement standard operating procedures for consistency and establish feedback mechanisms for continuous improvement.

Comprehensive packaging and shipping solutions for PCB backup boards

We provide to ensure their safe delivery. Each board is wrapped in moisture-proof kraft paper and sealed with polyester film for added protection. An MDF sheet is placed on top to prevent warping or damage during transit. Our meticulous packaging process guarantees that your PCB backup boards arrive in pristine condition, ready for immediate use in your manufacturing process.

Backup board loadability

We ensure efficient shipping of PCB backup boards by maximizing loadability, fitting 24 pallets into a 1*20GP container. Each pallet is securely stacked to optimize space while maintaining stability during transport.

To prevent fall damage, we place a sturdy wood frame between the pallets and the container door, ensuring that your PCB backup boards arrive safely and intact, ready for immediate use in your operations.

Lead Time and Storage

- Production Time: 7 working days for standard specifications

- Storage Guidelines:

- Maintain relative humidity below 80%

- Keep in original packaging

- Stack maximum 5 layers

- Use within 48 hours of opening in humid conditions

Why Choose Our UV Backup Boards

- ✅ 20+ years of specialized experience

- ✅ Customization options available

- ✅ Rigorous quality control

- ✅ Global shipping capabilities

Conclusion

In summary, UV coated white backup boards represent an advanced solution for PCB drilling applications, offering superior performance characteristics compared to traditional phenolic boards and water-based paint alternatives. Their enhanced hardness, smooth surface quality, and environmental benefits make them an ideal choice for manufacturers seeking reliability and efficiency in their production processes.

By adopting UV coated backup boards, companies can improve drilling efficiency, enhance hole quality, and contribute positively to environmental sustainability in the electronics manufacturing sector. As the industry continues to evolve, these innovative materials, particularly from regions like Guangdong, will undoubtedly play a pivotal role in shaping the future of PCB production.

FAQ

Q: Can the UV backup board be customized?

A: Yes, we offer customization in:

- Density (830/880/950 kg/m³)

- Thickness (2.0/2.5/2.7mm)

- Surface treatments

Q: What is the warranty period?

A: We provide a one-year warranty on all UV backup boards.

Q: How does the UV backup board impact drill bit lifespan?

A: The enhanced surface hardness typically extends drill bit life by 20-30% compared to traditional backup boards.