Our works

melamine backup board

pcb backup board

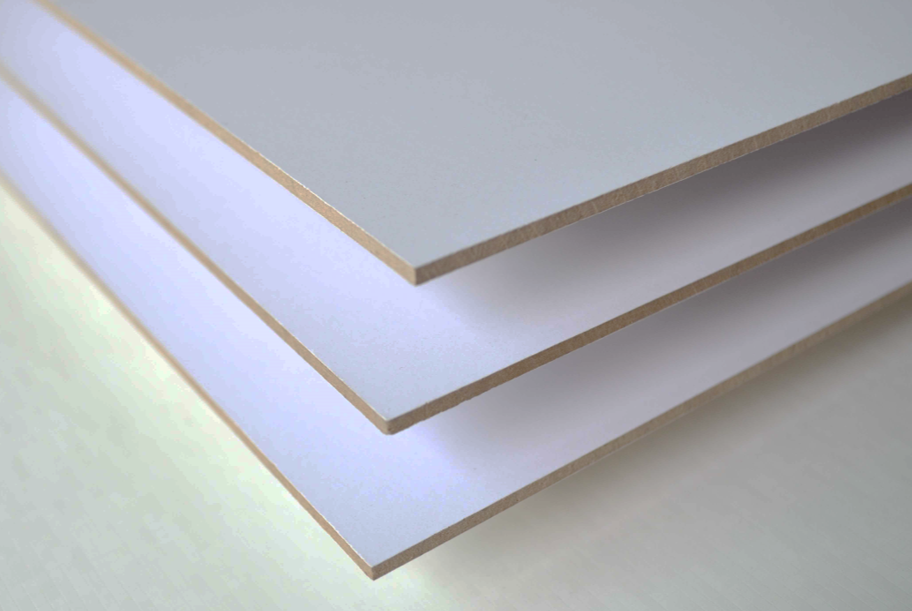

Melamine Backup Board for PCB Drilling

Table of Contents

Key Specifications and Features of Melamine Backup Boards

Superior Backup Materials Composition

- Composite Material: Melamine backing boards are primarily made from a composite material that includes melamine resin paper, typically using 75g titanium white paper.

- Thickness Consideration: 70g paper is too thin, leading to poor coverage, uneven surfaces, and insufficient tensile strength, making it prone to deformation.

- Manufacturing Process: The boards are produced under high temperature (175°C) and pressure (10 tons) for 70-80 seconds, ensuring durability and stability.

- Modified melamine resin is used as an adhesive. The addition of high-fatty chain raw materials during the production of melamine resin extends its storage life, reducing costs and improving production efficiency. A release agent is added to the adhesive before impregnating the paper, preventing sticking to the steel plates during pressing.The modified urea-formaldehyde and melamine resins effectively penetrate the gaps in fiber-reinforced substrates during high-temperature, high-pressure lamination, preventing moisture from entering the paper and wood fibers. As a result, this series of boards experiences significantly less wrap,twist change due to humidity compared to standard fiber boards.

Applications

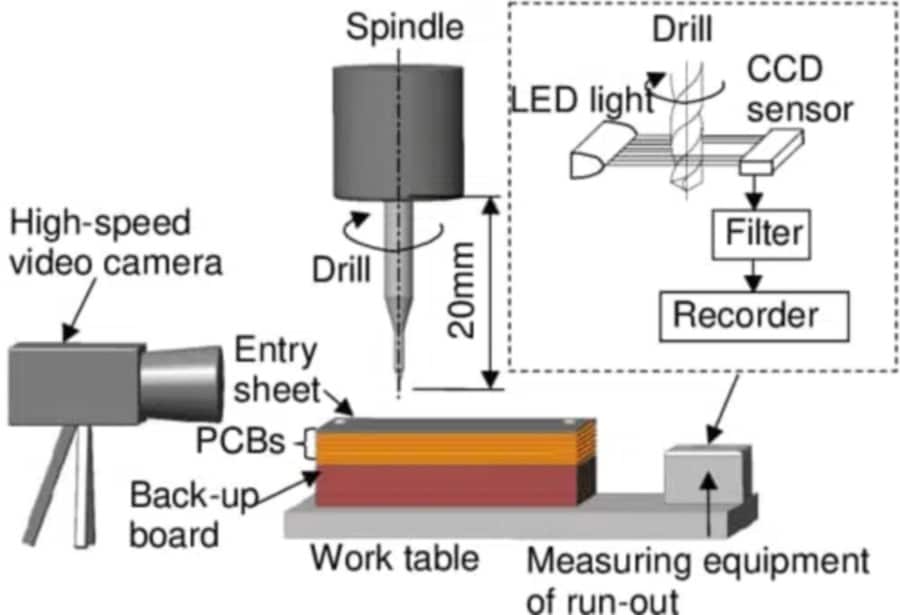

- PCB Drilling and Routing: Commonly used in PCB drilling, particularly for HDI (High-Density Interconnect) applications.

- Quality Improvement: Helps reduce exit burrs and enhances drilling properties.

- Cost-Effectiveness: Priced at nearly half that of phenolic boards while maintaining similar hardness performance. The wood chips produced during drilling are easy to clean, unlike resin which can lead to quality issues.

- Alternative to phenolic backing board Boards: Melamine boards serve as an excellent substitute for phenolic boards due to their comparable performance at a lower cost.

Specifications

- Thickness Options:

- Various thicknesses available:

- 2.7 mm (commonly 2.5 mm with sanded board at 880 kg/m³, achieving uniform thickness)

- 2.5 mm (standard using matte board at 830 kg/m³)

- 2.1 mm (primarily for the Korean market)

- 1.6 mm

- Various thicknesses available:

- Size Options: Common sizes include 37″x49″, 41″x49″, and 43″x49″.

- Warpage Tolerance: Typically ≤0.6%, indicating minimal deformation during use.

- Control Measures for Warpage:

- Selection of high-quality materials with pure wood fibers and moisture content controlled at 7-8%.

- Precise control over pressing pressure and time.

- Cooling time management post-pressing to minimize moisture absorption.

- Use of sturdy packaging to prevent deformation during transport.

- Control Measures for Warpage:

Color

- Appearance: Usually white, with some allowance for color variation.

- Surface HardnessHigh surface hardness reduces burr formation during drilling, which is crucial for maintaining the quality of wood fiber board made products. The hardness can reach 80 ±3 by adjusting adhesive ratios.

Performance Characteristics

- Drilling EfficiencyReduces drill temperature, minimizing wear on drill bits, thus improving the efficiency of production in the factory.

- Chip Removal: Facilitates easy removal of chips during the drilling process.

Advantages

- Cost-Effectiveness: Offers a favorable price-to-performance ratio compared to alternatives.

- Quality Assurance: High-quality melamine boards ensure precision in drilling applications, with consistent CPK values reducing needle wear and breakage.

- Versatility: Suitable for various types of PCB manufacturing processes.

Conclusion

Melamine backup boards are essential tools in PCB manufacturing, providing stability and enhancing the efficiency of drilling operations. Their specifications and performance characteristics make them a preferred choice for manufacturers seeking reliable and cost-effective solutions.This structured overview encapsulates the key features and specifications relevant to melamine backup boards in PCB applications. If you have any further questions or need additional details, feel free to ask! Order yours today and experience the difference!

Gelin electronic

has gained popularity for its white melamine backup boards, which are tested and used by top PCB manufacturers globally. Their boards are recognized for their reliability and performance in drilling operation

backup materials

a wide range of backup materials, are known for their excellent price/performance ratio. Their products are suitable for various drilling applications, making them a versatile choice.

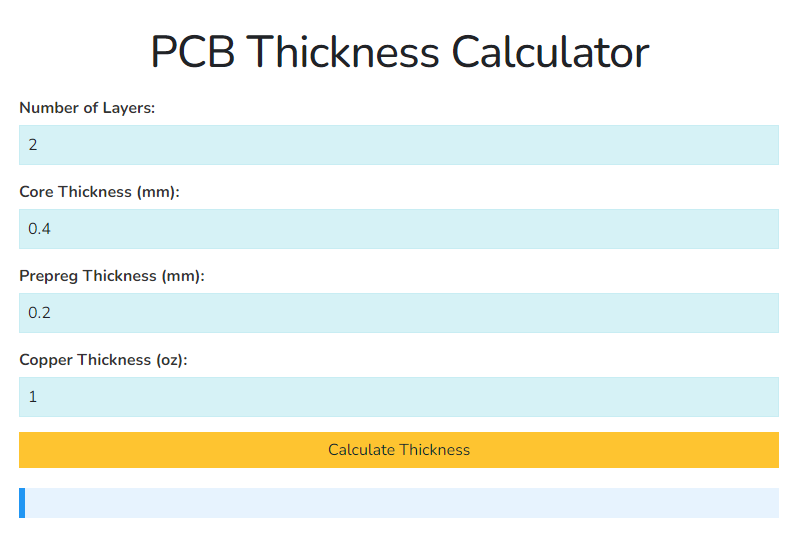

Cost Comparison of White Melamine Backup Boards vs. Other Materials

Typical Uses of White Melamine Backup Boards in PCB Manufacturing

- Micro Hole Drilling: White melamine backup boards are specifically designed for drilling small holes in PCBs. They provide a stable and supportive surface that minimizes damage and ensures precision during the drilling process, making them ideal for micro-sized holes

- Drilling Cushion: These boards act as a cushioning layer during mechanical drilling, protecting the PCB from chipping and splitting. This feature is crucial as the demand for smaller and more intricate PCB designs increases, especially in factory settings.

- Support for Multi-Layer Boards: The boards are suitable for use with multi-layer PCBs, providing the necessary support to maintain the integrity of the layers during drilling operations

- High Density Fiberboard Composition: Made from high-density fiber, white melamine backup boards offer excellent thickness consistency and flatness, which are essential for achieving high-quality drilling results

- Versatile Applications in sales: Beyond micro hole drilling, these boards can be used in various PCB applications, including flexible circuit boards and high-density interconnect (HDI) boards, where precision and reliability are paramount

- Cost-Effective Solution: The affordability of white melamine backup boards makes them a popular choice among manufacturers looking for effective drilling solutions without compromising on quality

These characteristics make white melamine backup boards an indispensable tool in modern PCB manufacturing, ensuring high-quality outcomes in various drilling applications.

wrap& bending

<0.6%

QUESTIONS /ANSWERS

How do I choose the right melamine backup board for my needs?

When selecting a melamine backup board, consider the following factors:

- Thickness: Choose a thickness that suits your drilling requirements.

- Size: Ensure the board size matches your PCB dimensions.

- Application Type: Some boards are better suited for specific applications, such as multi-layer or flexible PCBs.

- Supplier Reputation: Opt for well-known brands with positive reviews to ensure quality and reliability

How can I ensure proper handling and maintenance of melamine backup boards?

To maintain the integrity of melamine backup boards:

- Store them in a dry environment to prevent moisture absorption.

- Handle with care to avoid physical damage.

- Regularly inspect for wear and replace as necessary to ensure consistent drilling quality.

How does the material of a backup board impact drilling efficiency

The material of a backup board significantly impacts drilling efficiency in PCB manufacturing. Here are the key ways in which the material influences this process:

Impact of Backup Board Material on Drilling Efficiency

- Drilling Quality: High-quality materials like white melamine provide a stable surface that minimizes drill bit movement and enhances the precision of drilled holes. This is especially crucial as hole diameters decrease, where even minor deviations can lead to defects in the PCB.

- Burr Reduction: The choice of material affects the amount of burr produced during drilling. For instance, materials designed specifically for drilling, such as melamine or specially formulated composites, can significantly reduce exit burrs, leading to cleaner holes and less post-processing work.

- Thermal Management: Different materials have varying thermal properties. A good backup board material helps dissipate heat generated during drilling, which can reduce drill wear and prevent thermal damage to the PCB. This is particularly important for high-speed drilling operations where temperatures can rise rapidly.

- Flatness and Thickness Consistency: The flatness and uniform thickness of the backup board are critical for maintaining consistent drilling depth and quality. High-density fiber materials, such as those used in melamine boards, typically offer better flatness and thickness consistency, which contributes to overall drilling efficiency.

- Support for Complex Geometries: Advanced materials can conform to the topography of the PCB, providing better support during drilling. This is especially beneficial for multilayer and high-density interconnect (HDI) boards, where uneven surfaces can complicate the drilling process.

- Compatibility with Drilling Equipment: The material must be compatible with the drilling equipment used. For example, some materials may create excessive debris or wear on drill bits, while others may enhance the performance of the drilling process by providing better support and reducing friction

How does the flatness of a backup board influence drilling accuracy

Influence of Backup Board Flatness on Drilling Accuracy

- Surface Contact: A flat backup board ensures consistent contact with the PCB during drilling. If the board is not flat, it can lead to gaps between the PCB and the backup board, resulting in uneven support. This unevenness can cause drill bits to wander or misalign, leading to inaccurate hole placement and potential defects.

- Burr Formation: Flat backup boards help minimize burr formation on the exit side of the drilled holes. When the PCB is supported evenly, the drill bit can penetrate cleanly through the material without causing excessive tearing or chipping. Non-flat surfaces can create uneven pressure, resulting in burrs that can affect the integrity of the drilled holes and complicate subsequent processing steps, such as plating.

- Drilling Depth Consistency: Flatness contributes to consistent drilling depth across the PCB. Variations in the backup board’s flatness can lead to inconsistent drilling depths, which may result in incomplete hole penetration or damage to the drill bit and the PCB itself. This is particularly important for multi-layer PCBs, where precise depth control is crucial for maintaining layer integrity.

- Support for Complex Geometries: In PCBs with varying thicknesses or topographies, a flat backup board can provide the necessary support to accommodate these variations. If the board is not flat, it may not adequately support the softer copper layers on the PCB, leading to further inaccuracies and potential defects during drilling.

- Impact on Drilling Speed: A flat backup board can enhance drilling efficiency by allowing for smoother operation of the drill bit. When the backup board is flat, the drill bit experiences less resistance, which can improve drilling speed and reduce wear on the bit, ultimately leading to better overall productivity

What is the typical price range for melamine backup boards?

The price for melamine backup boards can vary based on specifications and order quantity. Generally, prices range from $1.59 to $3.17 per piece for bulk orders, with variations based on thickness and size